Materials

- Lomec

- Materials

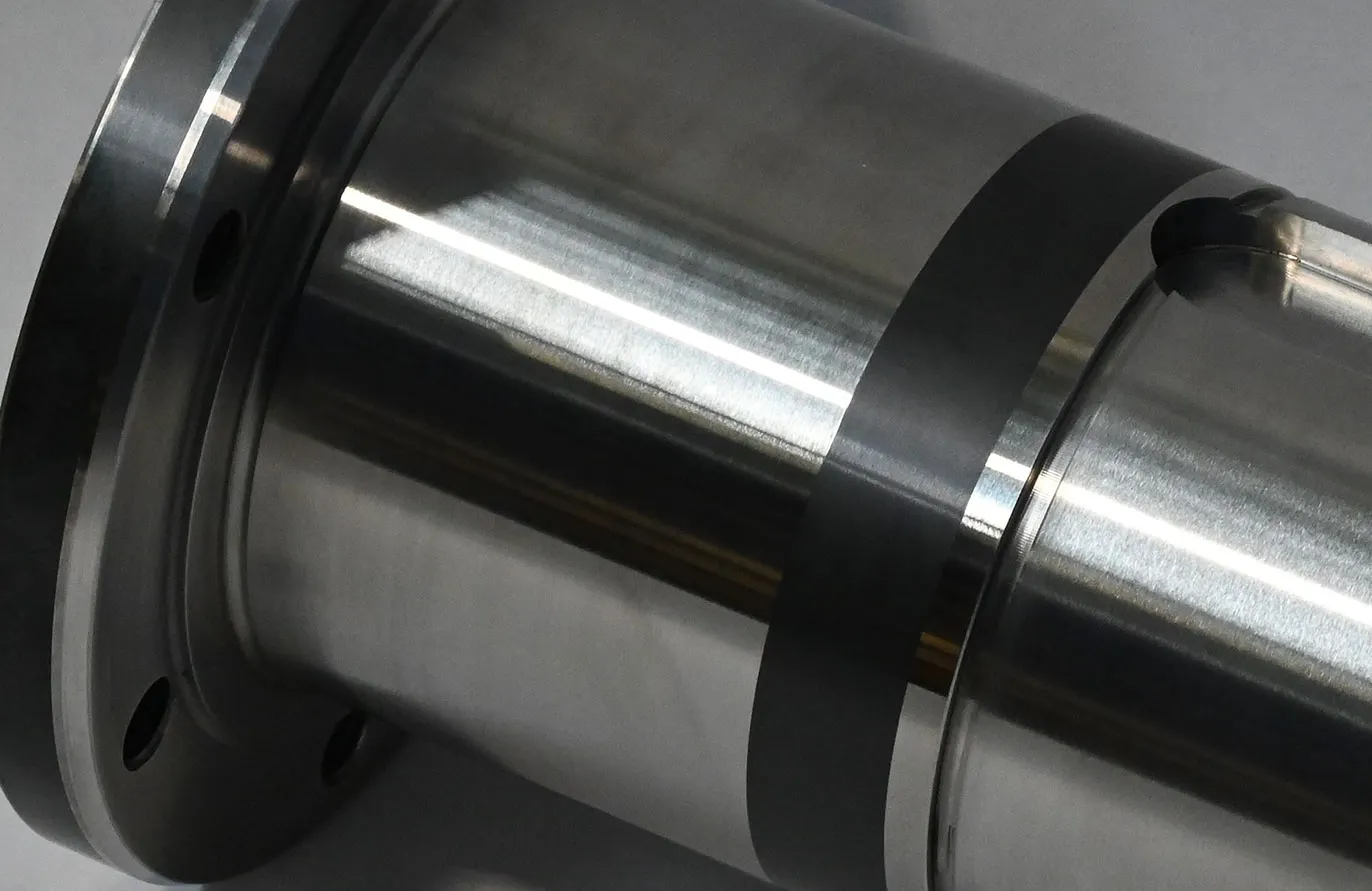

We specialize in the machining of metal components

Materials for every need

Lomec specializes in the machining of components made from industry-specific materials such as:

Cast Irons

(gray, Spheroidal, ADI, ...)

Cast iron is classified into several categories divided mainly according to microstructure and mechanical properties. Each category meets different needs based on the required properties (strength, ductility, wear, etc.). Lomec has many years of experience in most of the cast irons used in industry.

CARBON STEELS

(c45, s235jr...)

They contain mainly iron and carbon (up to 2%). The percentage of carbon determines the mechanical properties (strength, hardness, ductility).

They are often used for simple structures and mechanical elements in the industrial world.

ALLOY STEELS

(42CrMo4, 30CrNiMo8, 16MnCr5...)

These are steels that contain, in addition to carbon, other alloying elements such as chromium (Cr), nickel (Ni), molybdenum (Mo), vanadium (V), manganese (Mn), etc., to improve their properties.

Due to their characteristics, they are used in high-performance industries such as mechanical engineering, energy, and aerospace.

Due to their characteristics, they are used in high-performance industries such as mechanical engineering, energy, and aerospace.

STAINLESS STEELS

(AISI 304, AISI 316,..)

Stainless steels contain at least 10.5 percent chromium (Cr), which forms a protective oxide layer and makes them corrosion resistant .

Good mechanical properties and corrosion resistance make this class of steels particularly attractive to the Food, Chemical, Medical, Marine and Architectural Industries

SPECIAL STEELS

(X20CrMoV12, Inconel 718,...)

We are also able to process special steel alloys

These are steels designed for special applications with specific properties (heat resistance, wear resistance, or magnetism)

that are not routinely required in the industrial market, but which require specific attention during processing.

These are steels designed for special applications with specific properties (heat resistance, wear resistance, or magnetism)

that are not routinely required in the industrial market, but which require specific attention during processing.

aLLUMINUM

(Al70xx, Al 60XX, Al50XX ...)

We can also process the wide range of alumunium alloys in all their variants ( Heat treatable alloys Series 2xxx, 6xxx, 7xxx and non-heat treatable alloys Series3xxx, 5xxx) etc.

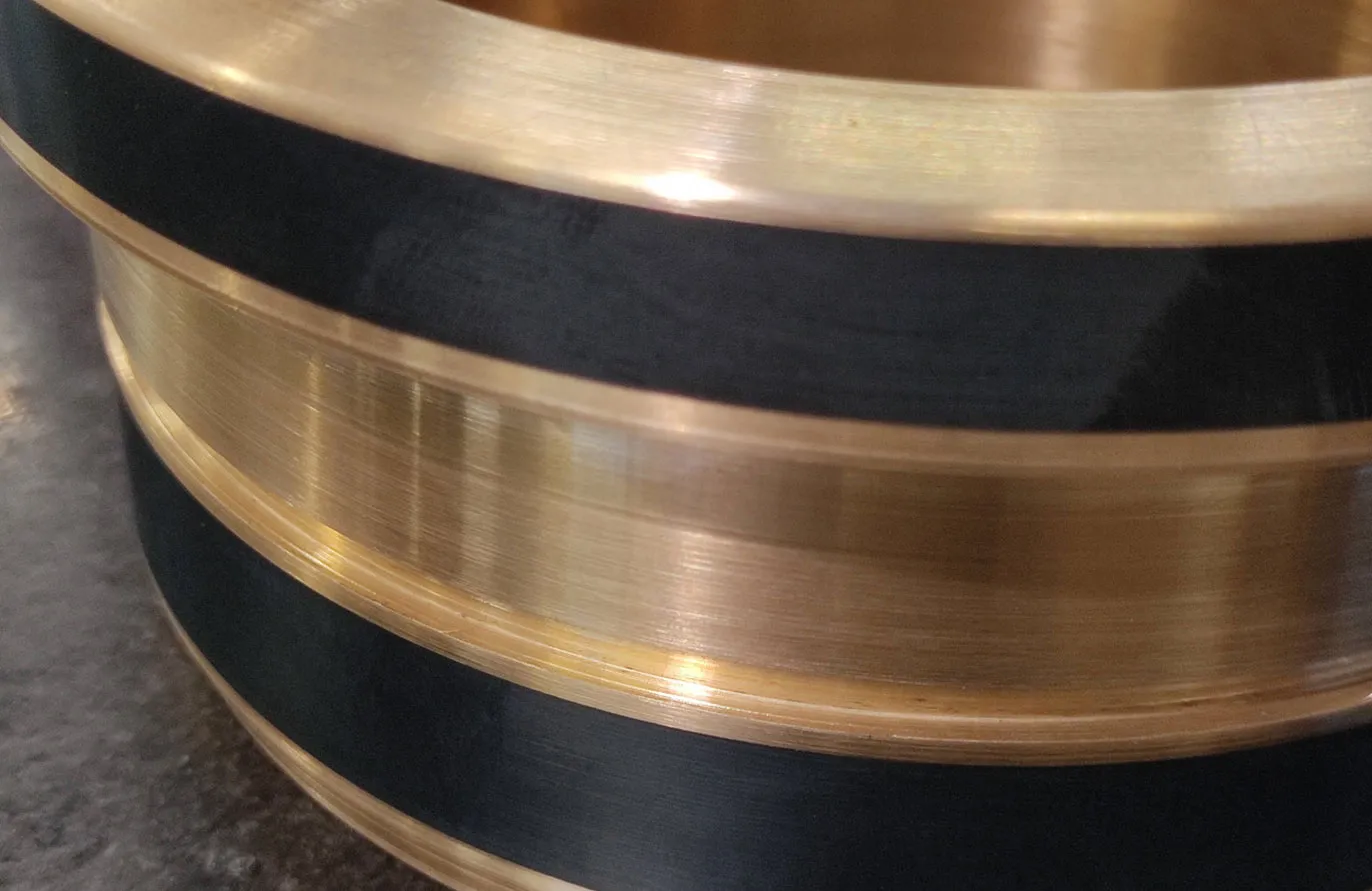

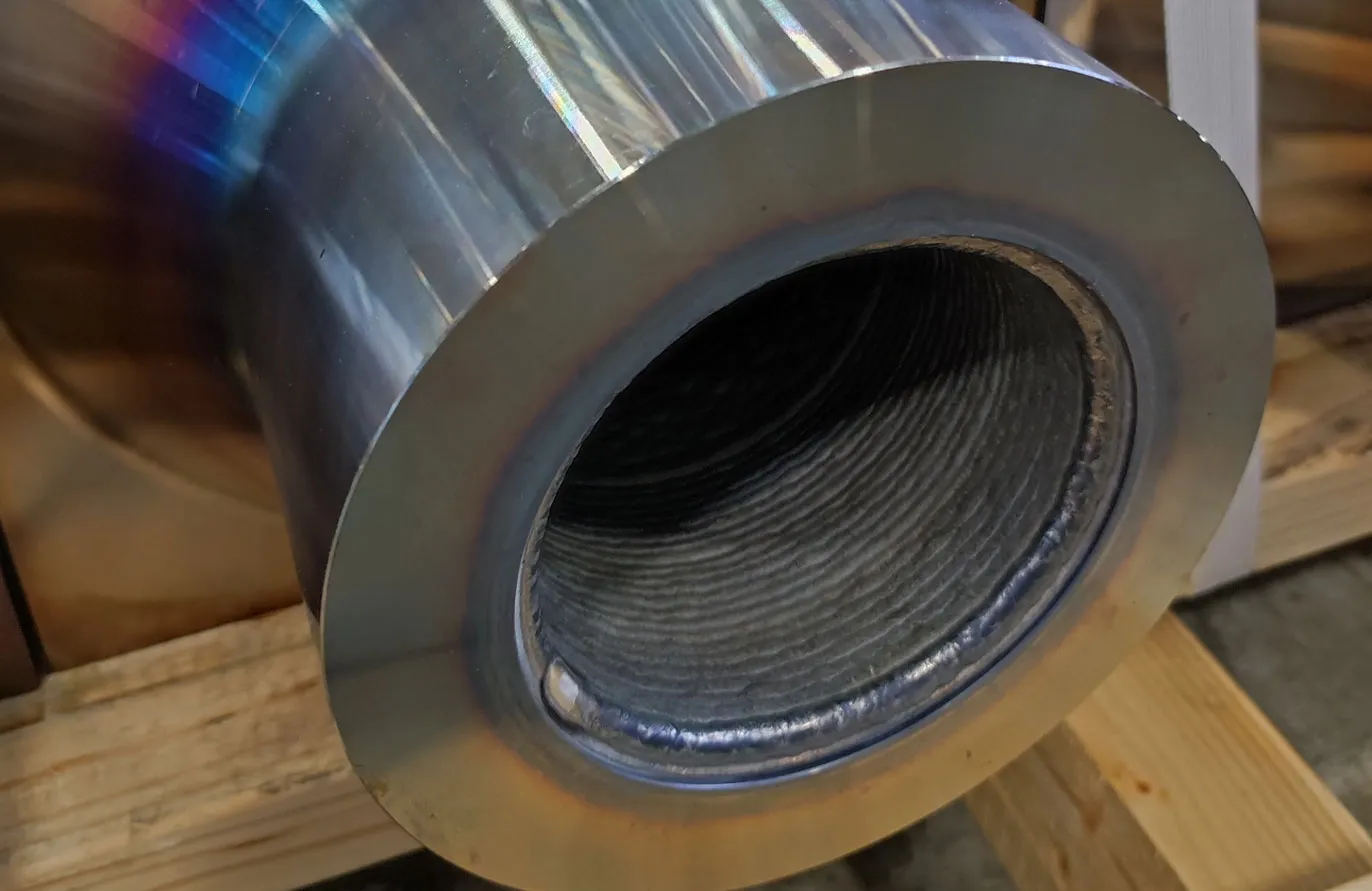

Special processing

In addition, we are able to perform special machining of components with anti-wear and anti-corrosion functions such as machining of components with welding coatings (CLADDING) which provide corrosion protection for steel pipes and valves used in special applications.

We also work on components with anti-wear and/or anti-corrosion functions with coatings with Chromium Oxide, Aluminum Oxide (Alumina), Zirconium Oxide (Zirconia), Cermet Carbide Tungsten-Cobalt WC-Co-(Cr), etc.

Contact us

Do you have a project to implement? Would you like more information?

Contact us for a quote